The Future of Manufacturing Models in Architecture

In the dynamic world of architecture, the integration of manufacturing models has ushered in a new era of precision, efficiency, and creativity. These models are not just representations; they are transformative tools that bridge the gap between conceptualization and realization. This article delves into the intricate landscape of manufacturing models, shedding light on their significance, advantages, and the substantial impact they have on the architecture industry.

Understanding Manufacturing Models

Manufacturing models refer to the detailed representations created to guide the production of architectural designs. These models can be digital or physical and serve various purposes throughout the construction process. They encapsulate the specifications, dimensions, and aesthetic attributes of a project, ensuring that architects and builders are synchronized in their vision.

The Evolution of Manufacturing Models

The journey of manufacturing models has evolved significantly over decades. Initially, architects relied heavily on hand-drawn blueprints and physical scale models to convey ideas. However, advancements in technology, particularly in computer-aided design (CAD) and 3D printing, have revolutionized this field. Today’s manufacturing models are more sophisticated, allowing for virtual reality (VR) and augmented reality (AR) experiences, enabling clients to engage with designs in immersive environments.

Key Advantages of Manufacturing Models in Architecture

The advantages of implementing manufacturing models in architecture are myriad. Here are some of the most significant benefits:

- Enhanced Communication: Manufacturing models provide a tangible representation of designs, facilitating clearer communication between architects, clients, and contractors.

- Increased Accuracy: By using precise digital models, architects can minimize errors and discrepancies during the construction phase, leading to significant cost reductions.

- Time Efficiency: Automated manufacturing processes and technologies expedite the model creation process, allowing faster project turnarounds.

- Better Visualization: Advanced rendering technologies enable stakeholders to visualize the final product more effectively, fostering improved decision-making.

- Versatility in Applications: From residential homes to towering skyscrapers, manufacturing models can be tailored to any architectural style and complexity.

Types of Manufacturing Models Used in Architecture

Different types of manufacturing models serve various purposes in the architectural process. Here are several prominent ones:

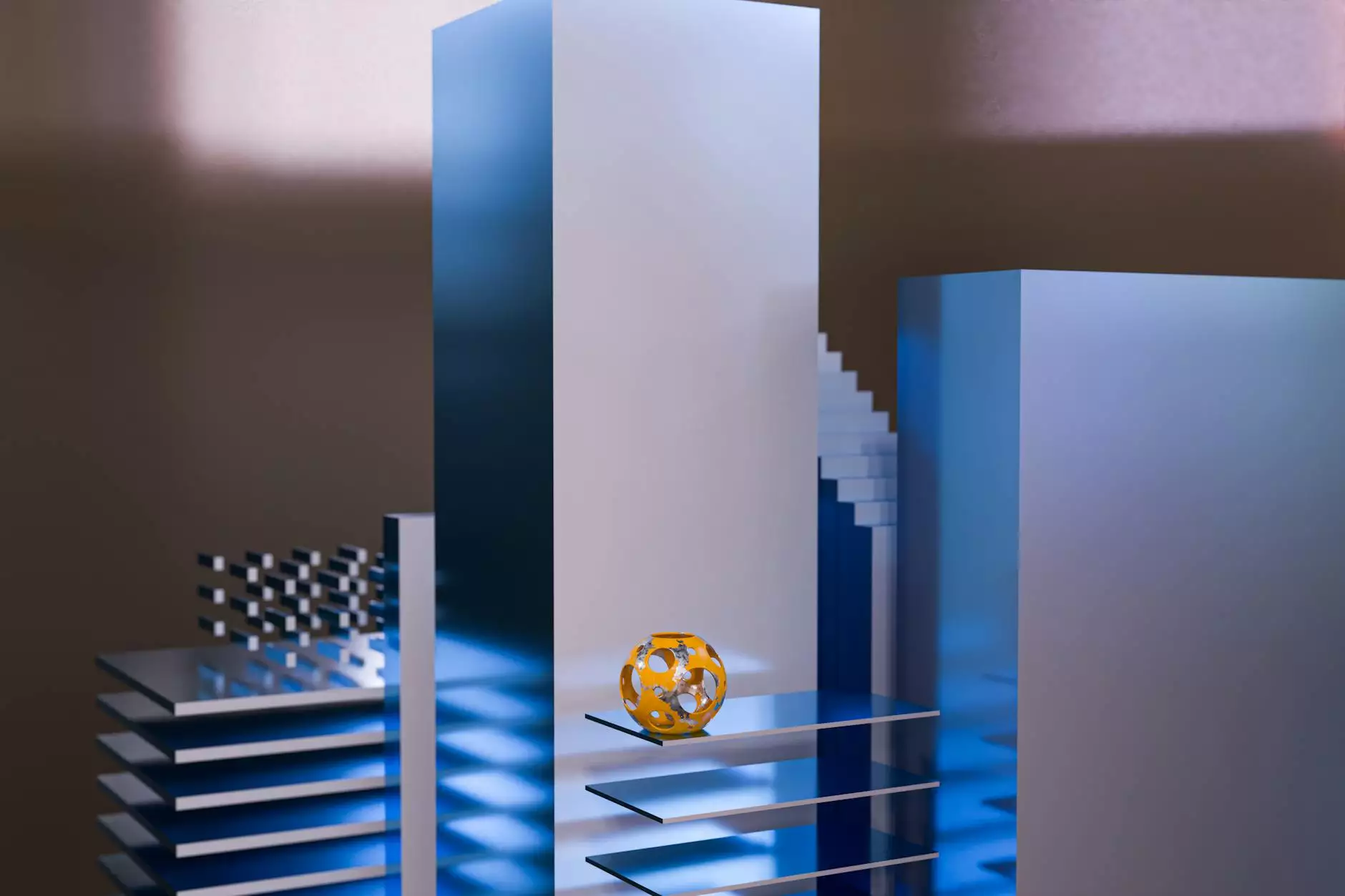

1. Physical Scale Models

Physical scale models are tangible three-dimensional representations built to scale. These models enable clients to assess the spatial attributes and aesthetics of a project. Typically constructed from materials such as foam, wood, or plastic, these models allow for hands-on interaction, giving a more realistic insight into the proposed designs.

2. Digital 3D Models

Digital 3D models are created using specialized software, offering architects immense flexibility to modify designs at any stage. These models can be animated and used in presentations, enhancing the understanding of the proposed structures.

3. Prototyping Models

Prototyping models focus on specific elements of a design, often created to test functionality or aesthetic appeal. These models can be either physical or digital and are vital in refining designs before full-scale production.

4. Rendering Models

Rendering models utilize high-quality renderings that showcase realistic lighting, textures, and materials. Architects use rendering to present finished visuals of the project, which helps clients visualize the final output.

Manufacturing Models and Sustainable Architecture

With the growing emphasis on sustainability, manufacturing models play a pivotal role in sustainable architecture. These models aid in:

- Material Optimization: By accurately simulating designs, architects can choose sustainable materials and optimize their use, minimizing waste.

- Energy Efficiency: Accurate models help assess the energy performance of buildings, leading to more efficient designs that reduce energy consumption.

- Lifecycle Assessment: Modeling software can analyze the environmental impact of materials and design choices throughout the lifecycle of the building.

The Role of Technology in Advancing Manufacturing Models

Technology has been at the forefront of advancing manufacturing models, enabling architects to push the boundaries of design and innovation. Some technological advancements include:

1. Computer-Aided Design (CAD)

CAD software has revolutionized the drafting and modeling process, allowing architects to create highly detailed and accurate models with ease. This software enables quick modifications, ensuring that changes can be implemented efficiently.

2. 3D Printing

3D printing technology has transformed the production of physical models. Architects can produce intricate designs quickly and accurately, which is particularly useful for prototyping and presenting concepts to clients.

3. Virtual and Augmented Reality (VR/AR)

The integration of VR and AR in architectural design allows clients to explore spaces before they are built. These immersive technologies provide an unparalleled experience, helping clients make informed decisions about design elements and layout.

Case Studies: Successful Implementation of Manufacturing Models

Examining real-world examples underscores the efficacy of manufacturing models in the architectural realm. Here are two notable projects:

The Guggenheim Museum Bilbao

Designed by Frank Gehry, the Guggenheim Museum Bilbao is a landmark in innovative architecture. The use of digital manufacturing models allowed Gehry to explore complex forms and dynamic shapes, resulting in a structure that is both functional and visually stunning. The model facilitated communication among stakeholders, ensuring clarity throughout the design and construction processes.

The Bosco Verticale (Vertical Forest)

Located in Milan, the Bosco Verticale consists of two residential towers adorned with trees and greenery. The project utilized a combination of digital models and physical prototypes to analyze the relationship between nature and urban living. The outcome demonstrates how manufacturing models can contribute to creating sustainable urban habitats.

Challenges in Manufacturing Models

While the benefits of manufacturing models are compelling, challenges still exist. Some of the primary obstacles include:

- High Initial Costs: The investment in advanced modeling tools and technologies can be substantial, particularly for smaller firms.

- Learning Curve: Mastering new technologies such as 3D modeling software and printing can require significant training and investment in skills development.

- Data Management: As projects grow in complexity, managing data effectively becomes critical, necessitating robust systems and workflows.

The Future of Manufacturing Models in Architecture

The future of manufacturing models within the architectural landscape is incredibly promising. As technology continues to advance, we can anticipate:

- Integration of Artificial Intelligence (AI): AI has the potential to enhance design efficiency, automate aspects of the modeling process, and offer data-driven insights.

- Greater Customization: Tailored manufacturing models that adapt to specific client needs and preferences will become increasingly prevalent.

- Improved Collaboration: Integrated platforms that allow real-time collaboration among architects, engineers, and clients will foster innovation and streamline project execution.

Conclusion

In conclusion, the role of manufacturing models in architecture cannot be overstated. They serve as essential tools that not only enhance communication and efficiency but also promote creativity and sustainability. As technology continues to evolve, architects will increasingly rely on these models to drive innovation and shape the future of our built environment. The evolution of manufacturing models is a testament to the enduring spirit of architecture—adapting, progressing, and redefining the boundaries of what is possible.